We improve efficiency through automated production lines to ensure high quality of valves. The accessories we use,

such as sealing strips and stainless steel bolts, nuts, gaskets, etc. are better than most of our peers. In terms of

processing accuracy, we use advanced equipment to achieve close cooperation.

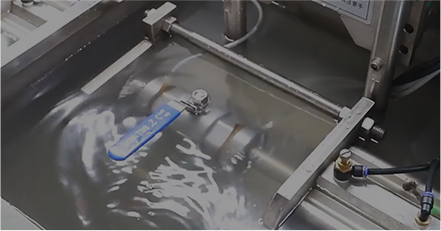

The perfect production process covers every link from raw material procurement to finished product inspection to ensure

that each product meets high standards. At the same time, we conduct multiple tests on raw materials and accessories to

ensure product quality.